Since inception back in 2002, Hydraproducts have been expanding their hydraulic product base whilst innovating and creating industry leading solutions for hydraulic based applications.

Hydraproducts recently bought out Fluidlink Hydraulics which has increased our already impressive product range, which now includes the renowned former Smiths Industries Mk3 power pack and the Ifor Williams trailer pack.

So, going back to the title of this blog, why should you choose Hydraproducts as your hydraulic power pack supplier?

Extensive product range and bespoke build options

Starting with Hydraproducts first mass produced pack, the Micro pack, we built on this base to create the Mini pack which was based on either an AC or DC power supply, with the latter commonly being associated with the commercial vehicle industry and tipping applications. Variations of these packs included box packs and bespoke builds to customer specification.

The online power pack configurator hosted on the Hydraproducts website has been a big success as customers can specify their build specifications down to a single component and generate a PDF file at the end which can be reviewed by Hydraproducts expert design team before the production process commences.

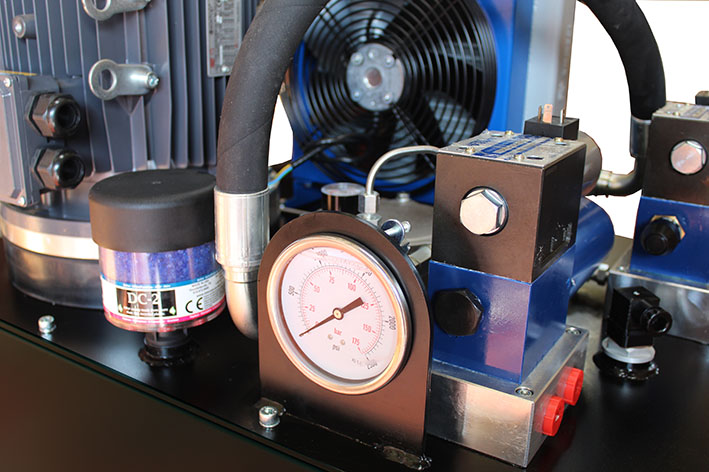

Hydraproducts then moved onto bigger projects and created the Standard power unit which comprised a modular based construction with standard range of components including Cetop 3 & 5 valves as well as bellhousing and coupling, accumulators and breathers.

The HPS unit was commonly used in marine applications such as Launch Recover Systems (LARS), as well as cranes, balers and compactors. But the HPS units aren’t the largest that Hydraproducts produce; the Bespoke system range suits large applications such as movie set props, valve actuation units, hydraulic test rigs and large offshore based applications.

As well as power packs and systems, Hydraproducts also have a large range of off-the-shelf components including gear pumps, valves and bellhousing/coupling which offer the customer that extra bit of customization when specifying their power pack.

Full product testing and technical support

Our experienced in-house engineers have a wealth of experience with hydraulic power packs and can advise on customer build taking into account the required fluid pressures, pump sizes and more importantly the type and footprint of the application it will be needed to power as well as its surrounding space requirements.

Using the correct fluid viscosity is crucial, and this depends largely on the type of application and the pressures it will be subject to. Hydraproducts have dealt with anything from water glycol units for nuclear applications to packs for commercial vehicle tippers so they are expert in guiding customers as to the correct hydraulic fluid to use in their system and where this fluid is available.

Hydraproducts also has its own in-house power pack test rig which fully tests each and every power pack before they are transported to their end customer.

The testing procedure measures fluid pressure and cleanliness to strict industry standards and stress testing to ensure that units can function correctly in hostile environmental temperatures and conditions.

Many rival hydraulics firms don’t accommodate for the testing of their products prior to dispatch, so lead an increased risk of dissatisfaction from their end customer when the power pack doesn’t perform as expected leading to potential production stoppages.