Hydraproducts was founded back in 2002 with the aim of taking on the hydraulic power marketplace with quality British made products and excellent aftersales service to back this up.

In the first part of the blog we will be looking at the Hydraulic Micro Pack which was the first power pack Hydraproducts produced after its inception, primarily due to the high demand for compact power packs needed for an ever expanding range of industry sectors.

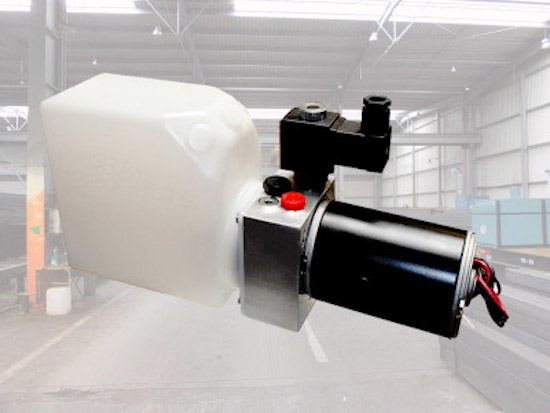

Micro Pack Range

Micro packs are a popular power pack as they are small, versatile units that can be used for a range of lifting applications where space is tight and other units just won’t be able to do the job. They were also the first unit that Hydraproducts produced as mentioned above.

They come in three types including a Uni-directional, Reversible and finally an ERA Actuator which we will look at below:

The Uni-directional Micro pack is ideal for powering disability lifts, cylinders, hydraulic clutches and clamps and can deliver up to 5 Litres per minute in a compact 87mm body. The uni-directional pack controls a single acting hydraulic cylinder and a solenoid valve is used to act with the force of gravity to lower a given load. When the motor has stopped, a check valve is used to hold the hydraulic cylinder.

The Reversible Micro pack powers double acting circuits such as those used in tensioning machines and positioning systems. It doesn’t need the use of solenoid valves to operate, instead using a dual pilot check valve which is responsible for holding loads and the pressure lines A and B are controlled using an adjustable relief valve.

An advantage of the reversible pack is that it can control hydraulic motors as well as double acting cylinders. It is constructed by high quality CNC machines so is a dependable sturdy power pack.

ERA Actuator Kit This kit is attached directly to cylinders and acts as a reversible power pack It was basically a development of the standard reversible power pack with added features including a single manual override which allows the actuator to move unhindered and not interfere with the dual pilot check valve setup.

Safety functions in the ERA Actuator have also bee improved with the addition of thermal relief valves which help prevent the actuator suffering over-pressurisation when instances such as thermal expansion or anomalous loads affect the actuator.

A common accessory for the ERA is mounting plates which can be mounted to the ERA body itself using a series of bolts and are known as ‘saddles’. The power pack and mounting plate are connected by O ring face ports. These ports are also a security feature as they help prevent leakage with their high quality seal.

The next blog in the series will be looking at our popular and extensive Mini pack range which, like our Micro packs, can be used for a wide range of applications in a number of industry sectors.